Experimental Physics II

Overview

General Contact:

Address:

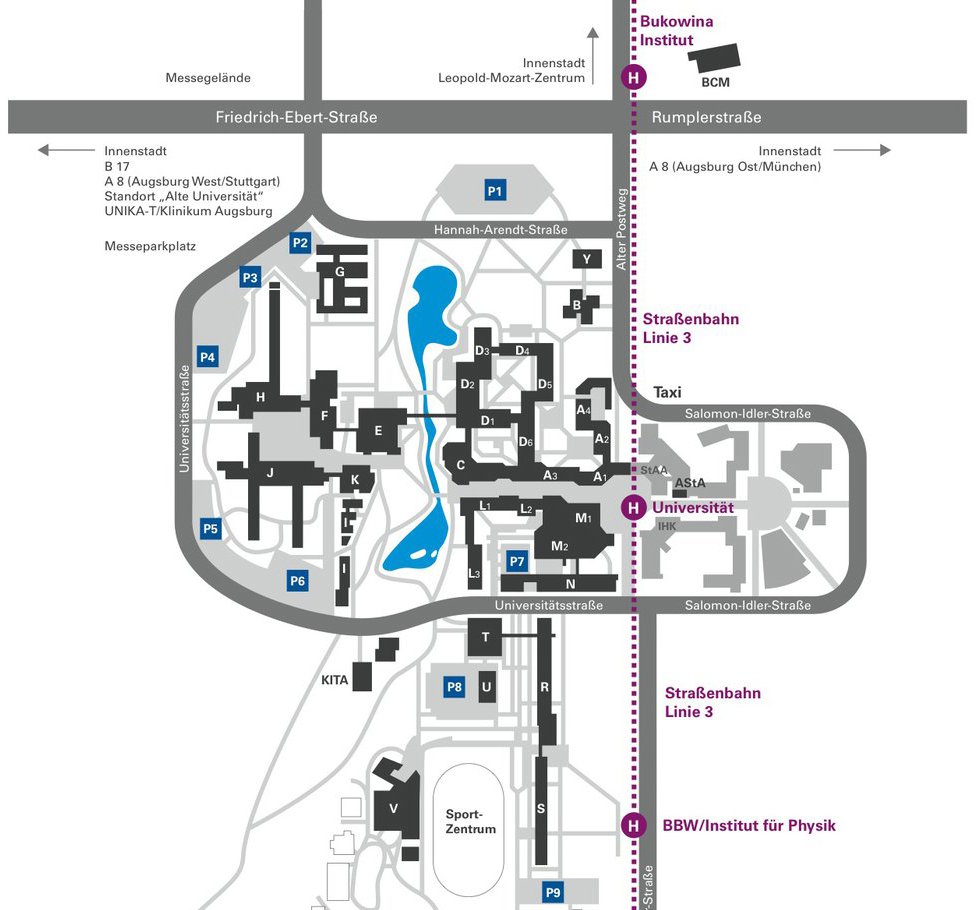

Experimentalphysik II

Universität Augsburg

Universitätsstraße 1

86159 Augsburg

Germany

Phone: +49 821 598 -3437 (Assistance)

Fax: +49 821 598 -3411

E-Mail: jutta.hampel@physik.uni-augsburg.de (Assistance)

Building: R